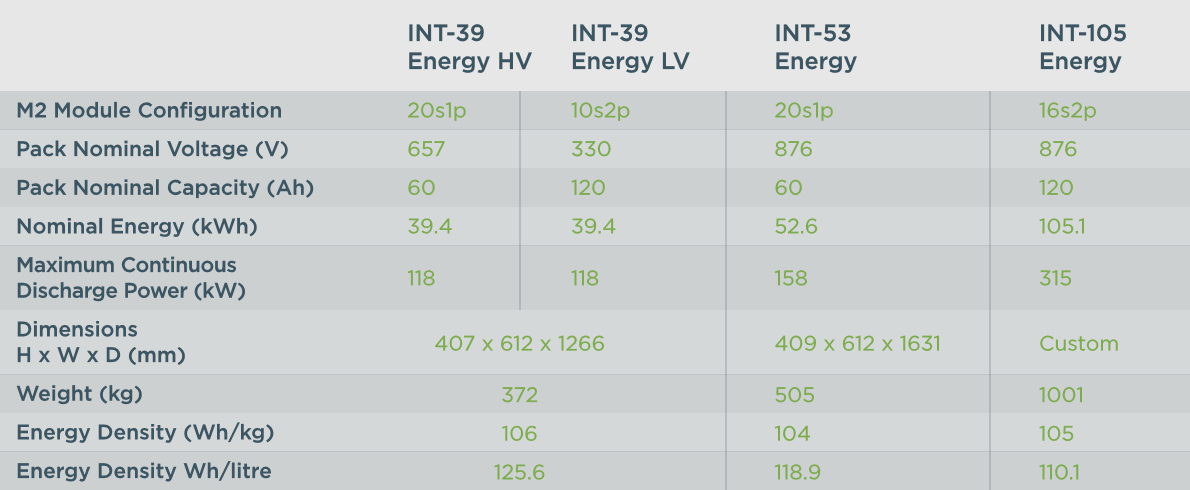

INT-39 Energy: High voltage battery systems

High voltage battery systems for commercial vehicle applications

Cells & Modules

- High energy 60Ah G/NMC cells, with Industry-leading Cycle life: 8,000 at 80% DoD. (4,500 at 100% DoD).

- High power 34Ah LTO cells, with Industry-leading Cycle life: 20,000 at 80% DoD. (15,000 at 100% DoD).

- Conductive cooling for every cell – no hotspots which prolongs battery life

- In house cell production at our state-of-the-art facility in Germany ensures the highest quality levels as well as guaranteeing quick delivery times.

- Modules of different configurations are available depending on the requirements of each application.

Subpacks & Packs

- Subpacks are made up three modules and their associated liquid cooling plates.

- Liquid-cooling plate: Every module is liquid cooled from connections external to the Subpack, which eliminates the risk of any leakages that could lead to thermal incidents.

- Battery Management Units in every module – detect redundant overtemperature in every cell

- Battery management system in an IP67 enclosure to create INTEGRATED packs or they are enclosed separately to act as stand-alone battery packs

- Reliable operation in EMC hostile environments

This system is made up of batteries and a Leclanché Battery Management System all integrated into one pack.

- Configurable for a large range of energy requirements

- Industry leading cycle-life

- Liquid-cooling and multi-layer fire containment

- Up to 1000 volts battery pack capacity

- Expandable by attaching packs in strings

- Road: ISO 26262 BMU Certified

- Rail: EN 50128 Safety Certified

- IEC 62928 Certified

We provide tailor made complete battery systems integrating battery thermal management systems and multistring communications fulfilling all railway applicable standards

Certifications

- Rail/ Road: ECE R-100 Revision 2 certified*

- Rail: EN 50128 Safety certified

- IRIS / ISO TS 22163 certified

- Road: ISO 26262 BMU certified

- IEC 62928 certified

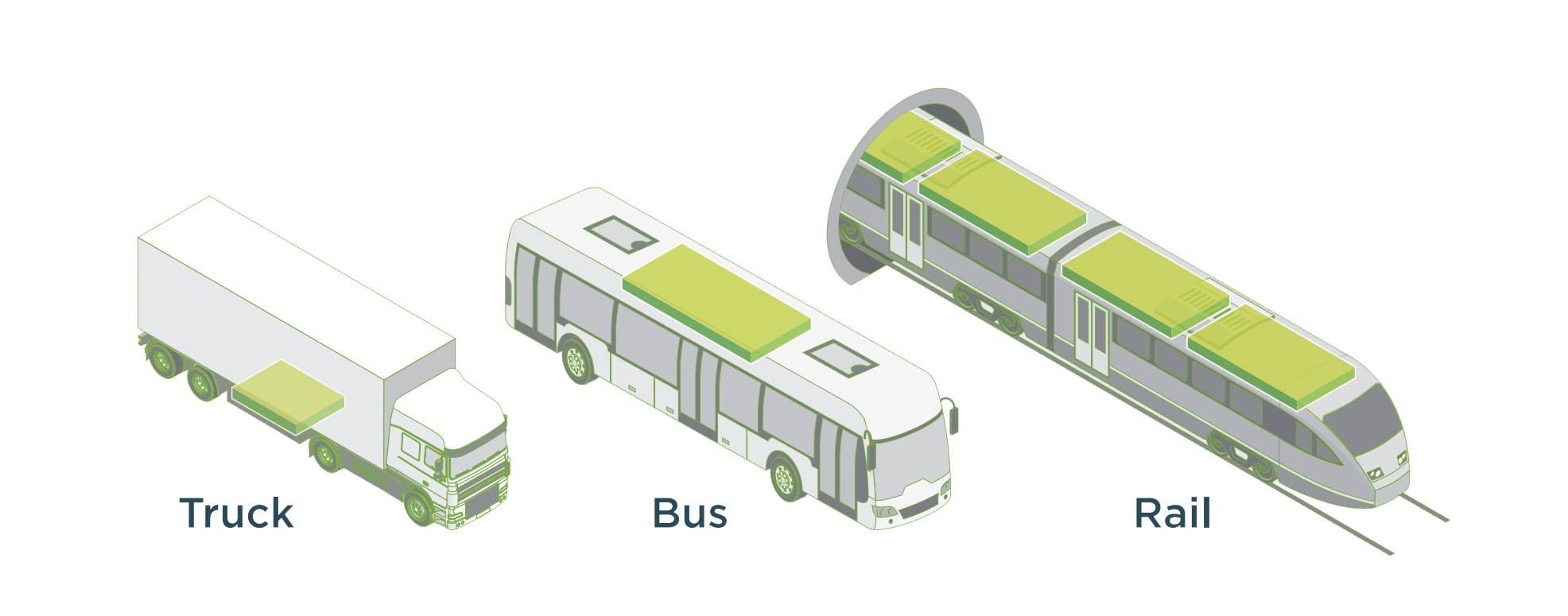

Applications

Operation Modes

Integrating a Leclanché battery system offers you a variety of significant benefits whether on fully-electric or hybrid trains and vehicles.

-

- Improved operational efficiency

- Lower running costs

- Substantial maintenance savings – typically 50% lower than diesel vehicles

- Quiet, odorless and zero-emissions

- Contributing to the transition towards cleaner mobility solutions

|

|

|

|

|

|---|---|---|---|---|

Hybrid

|

Regenerative

|

Peak

|

Strategic

|

Zero Emission

|

|

Achieve substantial fuel consumption savings by electrifying the drive system for vehicles or trains. |

Store and use energy regenerated from different sources, such as workload handling or regenerative braking, in full or hybrid-electric vehicles and cranes. |

«Shave» off operational load peaks and re-use stored energy. Allow a diesel engine to perform an optimal constant average load. This improves efficiency and reduces vehicle’s wear and tear. |

Switch from diesel to electrical power for auxiliary power units: tipping, refuse compacting, crane load handling, refrigerating and many other commercial vehicle and rail operations at port, etc. |

Leclanché’s commercial vehicle battery systems power your fully electric vehicle. No emissions, no fuel consumption and quiet operation. |

Benefits and Advantages

|

|

|

|---|---|---|

Performance |

Configuration |

Certification |

|

In-house designed and manufactured G/NMC and LTO lithium-ion cells with class leading energy density and cycle-life. |

Standardized of-the-shelf battery systems which are configurable to meet any ground transport client specifications. |

Type-approved battery systems means our packs are ready for operation immediately. |

|

|

|

|---|---|---|

Reliability |

Safety |

Manufacturing |

|

Proven battery systems that meet customer needs across ground transport segment |

Intrinsic safety from cell to pack level. Supplementary safety features can also be integrated if required. |

High capacity state-of-the-art automated cell and module production facilities based in Europe |

Commercial Vehicle Customers

|

|

|

|---|---|---|

|

|

|

|